Clinker microscopy

Grinding aid (GA) is an important ingredient in cement production, as they enhance mills' output, reduce electrical energy consumption and improve the performance of cements. GA is also highly beneficial for preparation and optimization of raw meal fineness, such as, mitigating homogenization issues in the resulting clinkers and enhancing clinkers' burnability.

A clinker of poor quality can consume up to 80% more energy (+10-15 kwh/ton), but this cannot be fixed by simply adding GA in the process.

GA is not a simple low-cost Band-Aid solution to be used to fix bad quality clinkers nor a miracle cure to compensate for problematic production conditions. It is rather an added value product to be used with the most optimized conditions.

Quality control on the clinker using clinker microscopy coupled with XRD and chemical analysis is thus a priority in order to optimize its manufacturing process and truly get the full benefits from GA. Evaluation of a clinker’s characteristics provides valuable and precise information on the different steps of its fabrication:

⦁ raw meal preparation

⦁ composition and stability

⦁ kiln operation conditions

⦁ risk of build-up and ring formation

⦁ clinker granulation…

It also informs on some further important complementary issues regarding the early/late strength development, setting time and workability of concretes that are very often neglected or unknown.

Clinker Microscopy, with our expertise, is a powerful tool that identifies the composition, distribution and micro texture of the clinker phases. It allows to assess the quality of the raw material preparation, to monitor the kiln operating conditions (flame impact, residence time, pre-cooling, and cooling conditions), thus leading to the production of a higher-quality clinker and to thermal and power energy savings.

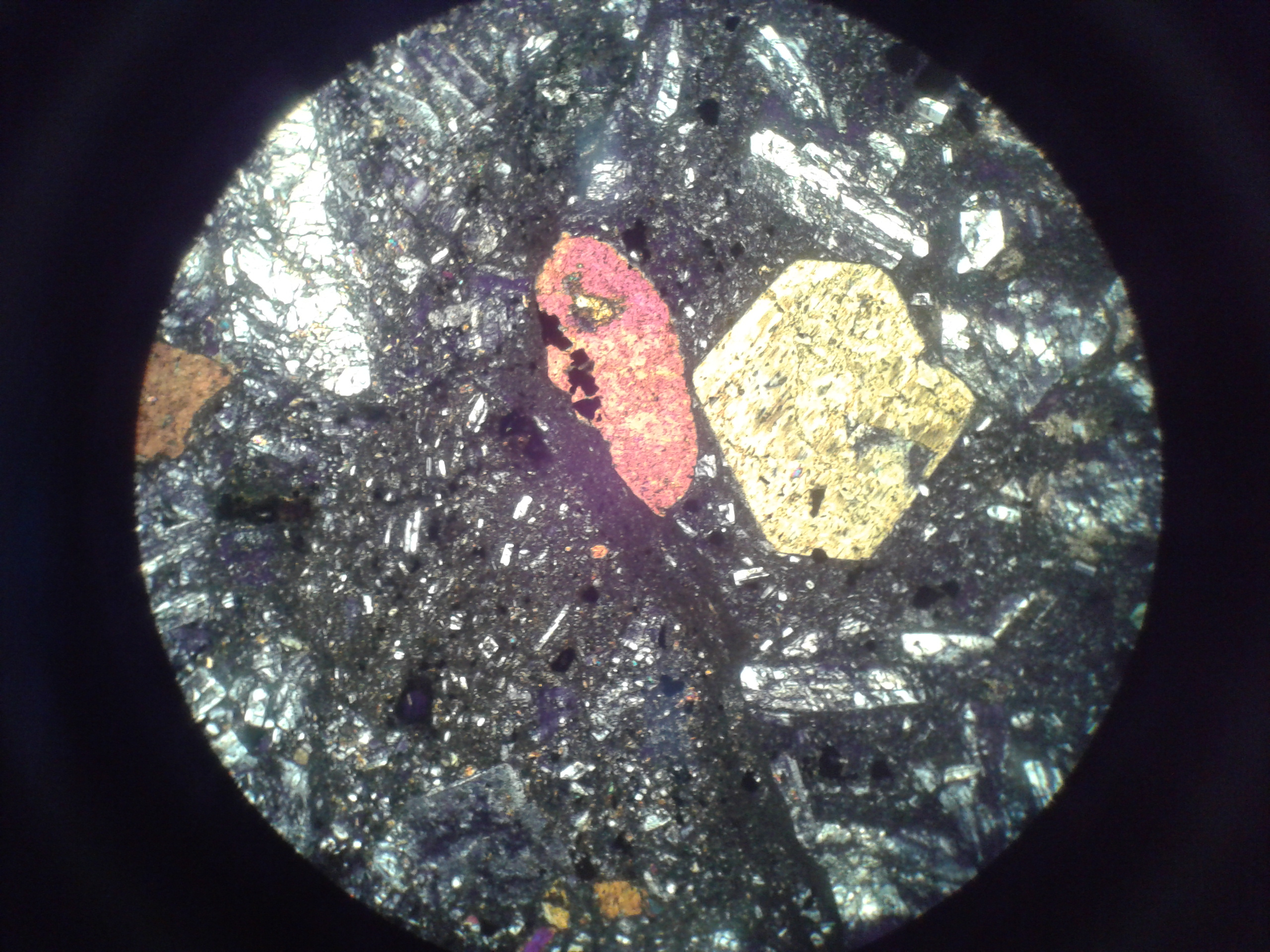

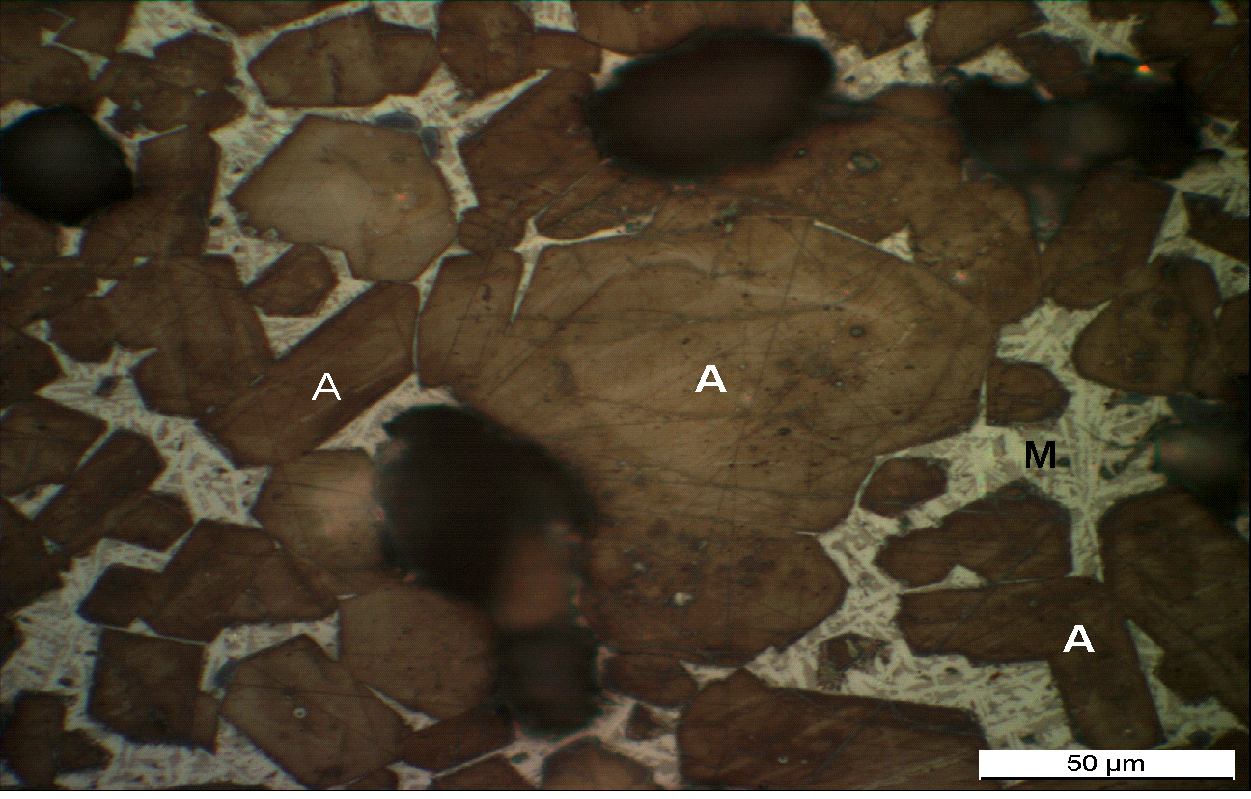

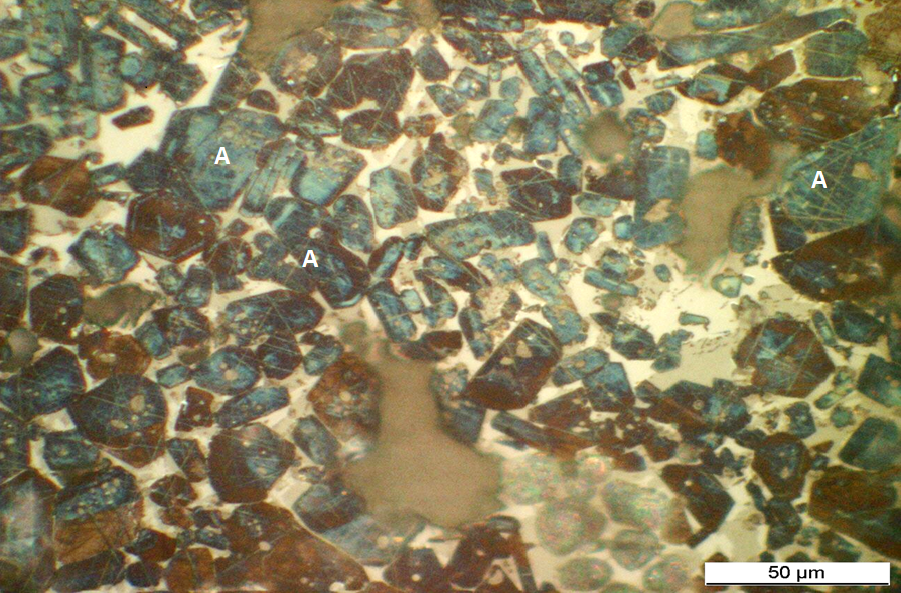

Here is an example of two different grades of clinkers assessed through microscopic analysis:

Bad quality clinker:

- Big Alite crystals (A) related to long residence time, being much less reactive and hard to grind.

- Result in higher thermal and power consumption.

Good quality clinker:

- Small Alite (A) crystals related to short residence time, being much more reactive and easy to grind.

- Allow thermal and power savings and increase SCM addition.

Prodexim International offers technical assistance to plant operations to improve and optimize clinker quality. We prioritize innovation, customer support through effective partnerships and bring higher added value to our services. Our expertise in process optimization allows for reduced energy consumption and production costs, all while producing high-quality clinker, and allowing for a better use of supplementary cementitious materials (SCM).

Additional microscopic analysis (mining and industrial residues)

-

Service on demand. Please contact us for more details.